Collecting the data

Vibration data mainly consists of velocity and acceleration magnitudes along with temperature and often various derived quantities like different fourrier transforms and signal envelops signifying different degradation causes ands tates. Data was collected over a period of 2 years from two sites of IOCL, at Bhubaneshwar and Delhi sites from mainly 3 different types of equipments. Pumps, Compressors, Fire Engines of varying make and models. Vibration sensors were installed on site for manual condition-monitoring before it can be automated. The sensors are manufactured in house along with the dashboar software for monitoring and displaying readings in realtime.

Data Preprocessing and Training

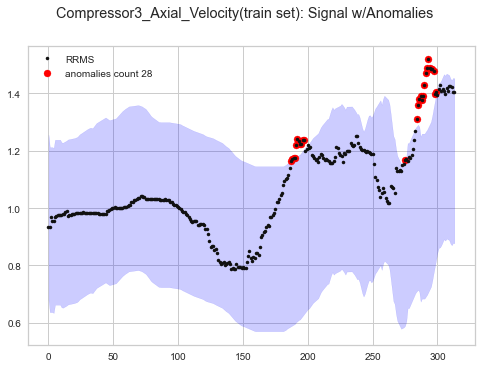

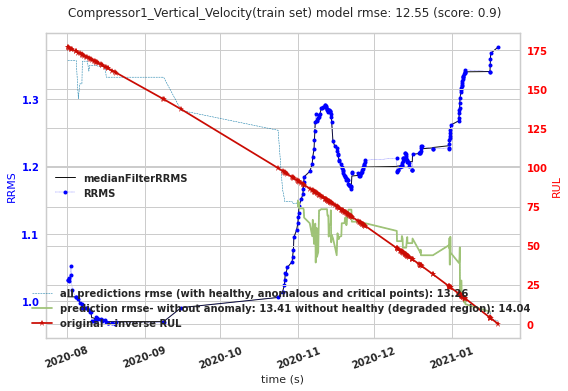

Working with a team of research scientists and data engineers various research papers were implemented to clean data and extract usable trends. Data preprocessing mainly involved performing multiple smootheing techniques, domain specific filtering and fitting different curves to project the signal for interpolation. Since the equipments have specific behaviour according to their make and models, equations were developed specific to the domain. Since the data isn't labelled, to form a trainable dataset various forms of labelling was performed generating an output health indicator under the supervision of research scientists with domain expertise.

Model training were performed by utilizing around 21 regressions models along with LSTMs and autoencoders and comparing the performance of each to finalize one and tuning it for inferencing. Autoencoders were used for anomaly usecases whereas Regressional algorithms were used for predicting remainng useful lives of the equipments.

Retraining and Deployment

It's a well known phenomena that once a model is deployed it's accuracy starts decreasing. Either because the environment has evolved or their are new parameters at work influencing the system. This is called model drift. An inhouse autu ML software was developed to perform retraining by selecting appropriate configuration and automating model training.

Deployment was done by using the autoML software and adding provisions to integrate the realtime inferencing on both the dashboard webapp as well as inferencing on edge (IOT integration) depending on the usecase.

Technologies used and skills learned were:

- Python3

- Tensorflow

- Pycaret

- Curve Fitting and mathematical modelling

- Interpolation and statistical learning methods

- MLflow

- IOT

- Web app and IOT integration for inferencing

- Extensive Research on Time series data processing and hyper parameter tuning